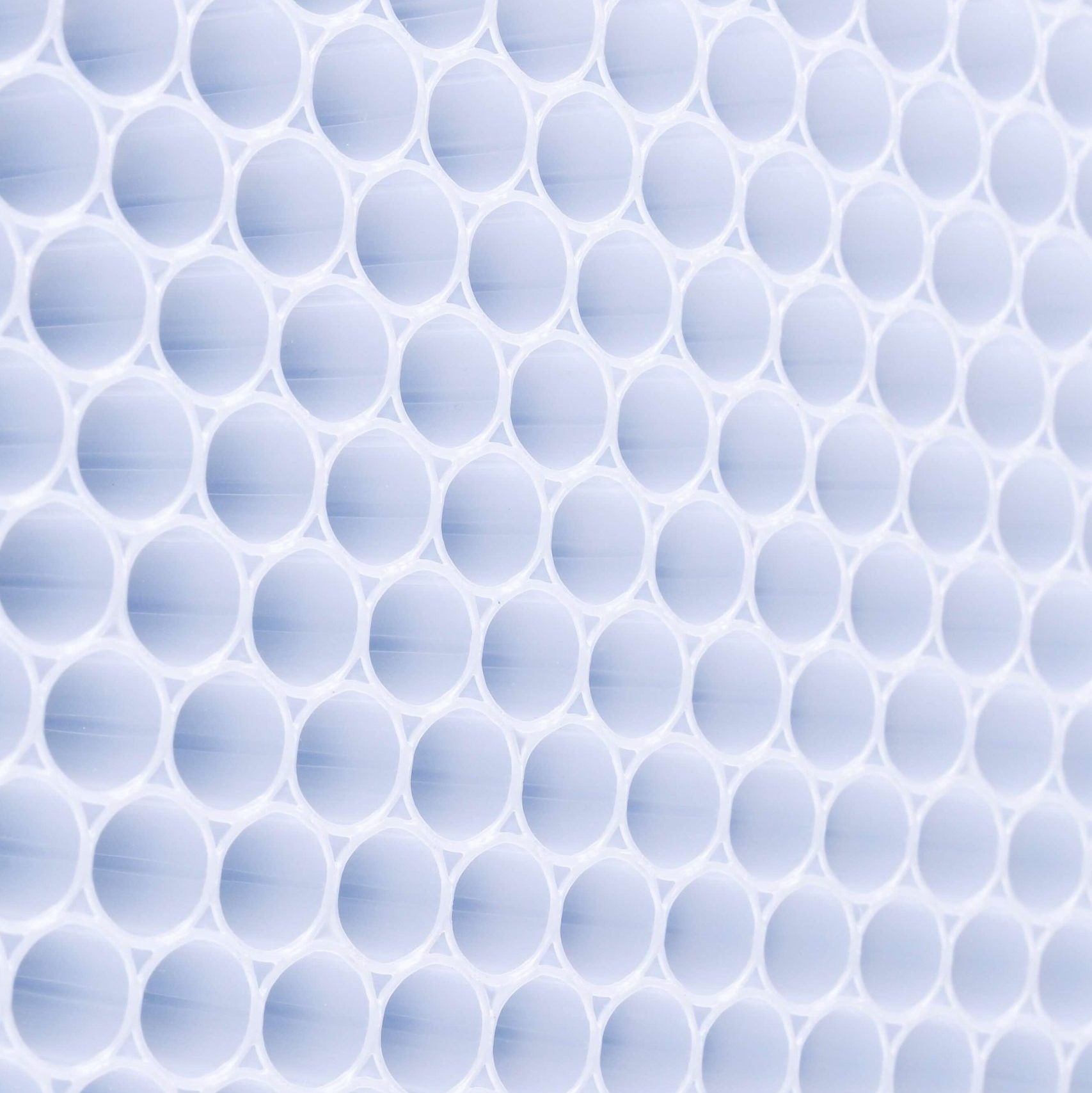

PP Honeycomb Core

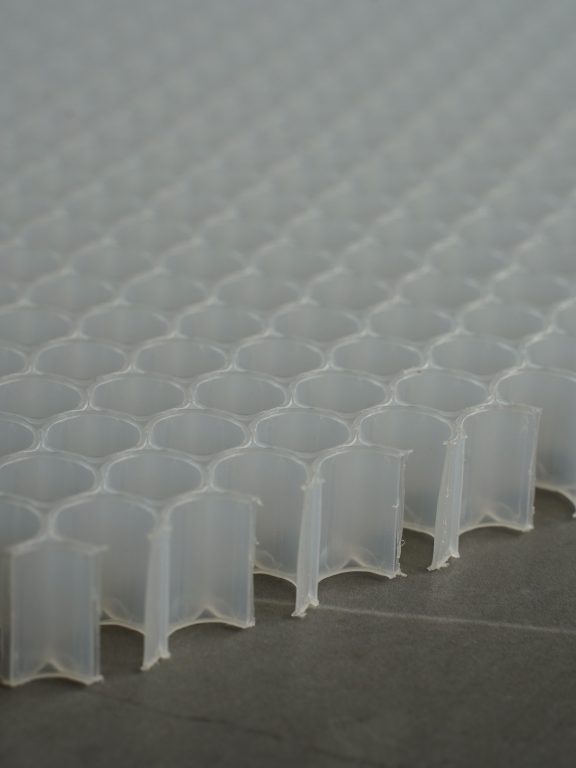

PP Honeycomb Core is a high-performance structural material made from polypropylene. It features a hexagonal honeycomb structure, which mimics natural honeycomb geometry to offer excellent compressive, shear, and bending strength while minimizing weight.

Its unique combination of light weight, high stiffness, and environmental resistance makes it ideal for industries that require strong yet lightweight materials. From automotive panels to marine decks, construction partitions, and packaging solutions, PP honeycomb core supports structural integrity without sacrificing energy efficiency.

In addition to its performance, the material is fully recyclable, thermoformable, and compatible with a wide range of laminates and surface treatments (such as CFRT, fiberglass, or aluminum). This makes it a versatile solution for both standard and custom composite panel configurations.

Specificities

PP Honeycomb Core panels are engineered for performance in challenging environments. Their closed-cell polypropylene construction resists water, chemicals, and temperature changes, making them suitable for both indoor and outdoor use.

Key performance characteristics:

- High Strength-to-Weight Ratio

The honeycomb structure distributes stress evenly, maintaining strength with minimal weight. - Energy Absorption & Vibration Dampening

Ideal for automotive, marine, and industrial use where impact or vibration is present. - Waterproof & Corrosion Resistant

Resistant to moisture, mold, and corrosion—perfect for humid or exposed environments. - Thermoformable & Customizable

Easily molded, cut, or bonded into different shapes and formats. - Recyclable & Environmentally Friendly

Made from recyclable polypropylene, in line with sustainable manufacturing practices. - Temperature Resistant

Performs well in both low and high temperature conditions (from -40°C to +80°C).

Products Customized

At Sinomate, we understand that every project is different. That’s why we offer full customization services for our PP Honeycomb Core panels to match your exact requirements. You can choose from a wide range of thickness options, cell sizes, and panel dimensions. We support custom lamination with CFRT, fiberglass, aluminum foil, or decorative films depending on the functional and aesthetic needs of your application. Optional layers such as PU foam or anti-slip coatings can also be added. Whether you need large-format panels or CNC-cut components, we are ready to deliver precision-engineered solutions with fast lead times and global support.

Structure of Carbon Fiber PP Honeycomb Panels

The carbon fiber PP honeycomb panel is a composite sandwich structure that integrates performance, efficiency, and aesthetics. The top and bottom skins are made of high-strength carbon fiber, bonded seamlessly to a lightweight polypropylene honeycomb core. This configuration delivers a panel that is incredibly stiff and resistant to deformation, while still being significantly lighter than metal or solid laminate alternatives. The honeycomb core features a circular cell geometry, which effectively distributes load, absorbs impact, and reduces vibration. Together, this structure ensures durability, reduced weight, and superior thermal and acoustic performance, making it ideal for structural and functional components across automotive, marine, and industrial sectors.

Truck body

Lightweight yet durable panels that reduce vehicle weight while maintaining high structural integrity. Ideal for logistics vehicle walls, roofs, and floors.

RV

Provides a balance of strength and comfort, used in RV walls, ceilings, and furniture. Excellent thermal and acoustic insulation for long-distance travel.

Truck Parts

Perfect for truck floors, partitions, and side panels. Resistant to impact, moisture, and chemicals. Offers easy processing and installation.

Marine

Ideal for boat decks, cabin walls, and bulkheads. Corrosion-resistant, lightweight, and built to endure marine humidity and salt exposure.

WHY CHOOSE US

10+ Years of Expertise

With over a decade of focus on thermoplastic honeycomb and composite materials, we’ve developed deep technical expertise and a reputation for delivering high-performance, reliable solutions across global industries.

Trust

From Germany to the United States, from Brazil to Southeast Asia, our products are trusted by manufacturers in automotive, construction, marine, and logistics sectors. We’re proud to be a long-term partner for some of the world’s most demanding applications.

Quality

Every panel we produce undergoes strict quality control, from raw materials to final lamination. Our ISO-certified processes ensure that every delivery meets your technical and safety expectations.

Innovation

We invest in advanced equipment, including precision cutting, high-speed lamination, and automated assembly lines. Our R&D team continuously explores new materials and processes to meet evolving industry needs.

FAQ

Q1: What is a PP honeycomb core?

PP honeycomb core is a lightweight, hexagonally-structured material made from polypropylene. It is commonly used as the internal core of composite panels to provide high stiffness and strength with minimal weight.

Q2: Where is PP honeycomb core typically used?

It is used in automotive, marine, construction, and packaging industries—as a core material in sandwich panels, floorings, partitions, and protective packaging systems.

Q3: Can I customize the thickness, cell size, or panel dimensions?

Absolutely. We offer various customization options including core thickness, cell size, sheet width and length, and compatibility with different surface laminates.

Q4: Do you offer OEM/ODM services?

Absolutely. We support OEM, ODM, logo printing, pre-assembly, and more.