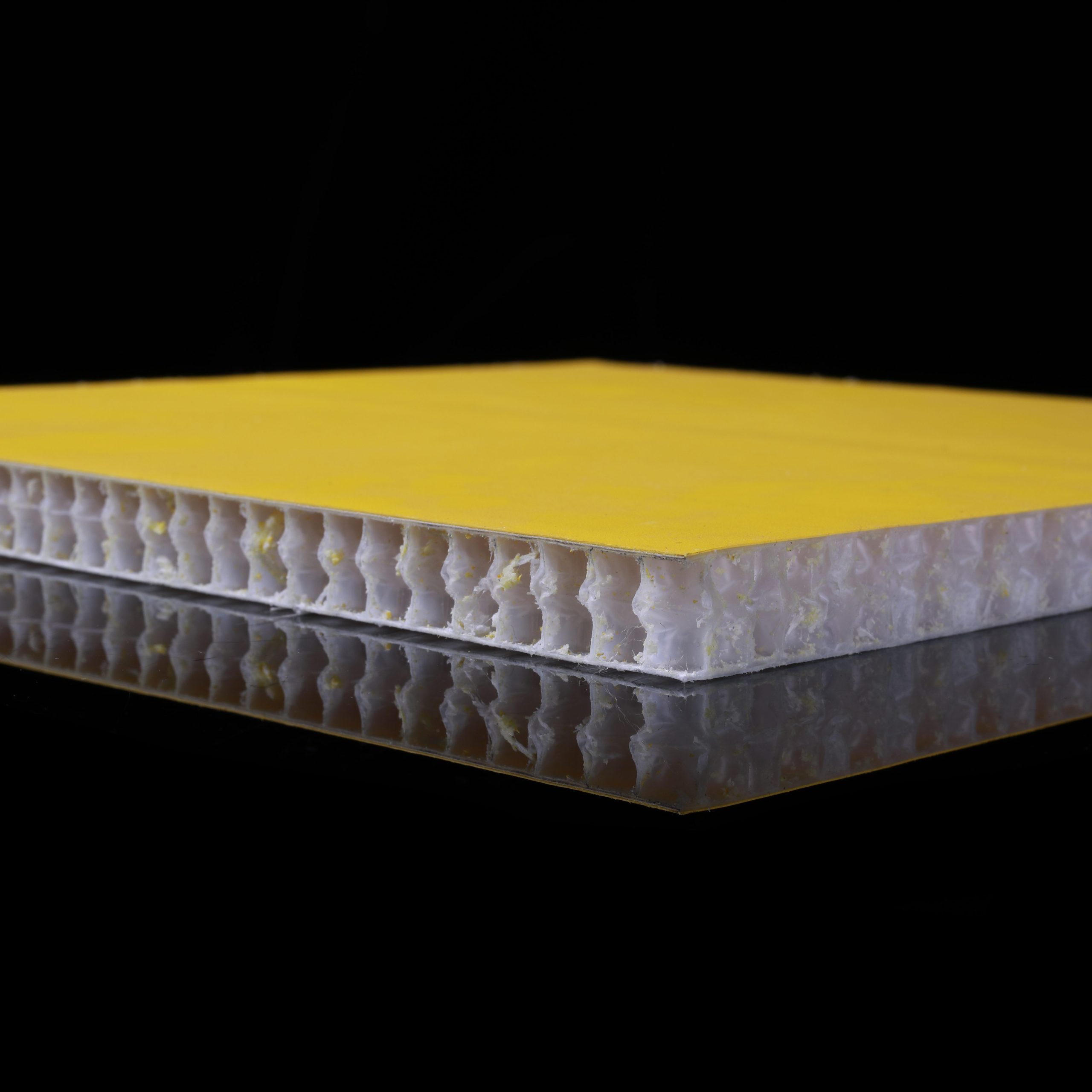

PP Honeycomb Panel

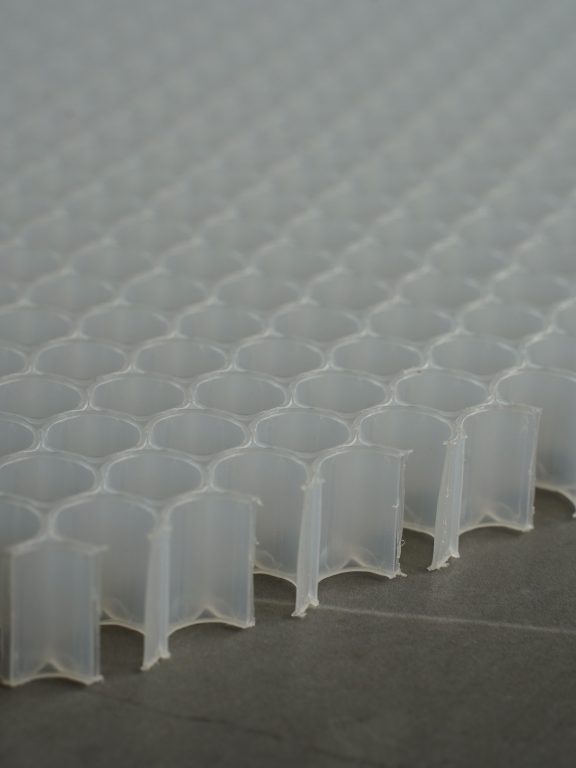

PP Honeycomb Panel is a lightweight composite panel consisting of a polypropylene (PP) honeycomb core sandwiched between two skin layers, which can be made of materials such as CFRT, fiberglass, aluminum, or other laminates. This structure provides excellent strength-to-weight ratio, impact resistance, and dimensional stability.

Engineered for durability and versatility, PP honeycomb panels are widely used in automotive interiors, construction walls and partitions, marine flooring, logistics packaging, and cleanroom environments. Their moisture resistance, chemical stability, and full recyclability make them an environmentally friendly and cost-effective alternative to traditional materials.

Customized surface treatments and panel thickness options are available to meet the requirements of various industries and applications.

Specificities

PP Honeycomb Panels are designed to deliver exceptional mechanical and environmental performance in a wide range of applications. Combining the strength of composite skins with the lightweight honeycomb core, these panels offer reliable structural support without added bulk.

Key performance characteristics:

- Superior Rigidity with Minimal Weight

The sandwich structure provides outstanding bending stiffness while remaining extremely light. - Excellent Impact Resistance

Withstand shocks and pressure, making them suitable for transport, construction, and protective enclosures. - Moisture & Chemical Resistance

Non-absorbent and unaffected by most chemicals—ideal for harsh or wet environments. - Thermoformable & Easy to Process

Panels can be shaped, cut, or bonded to meet custom design needs. - Eco-Friendly & Fully Recyclable

Constructed from polypropylene and compatible laminates, enabling sustainable end-of-life handling. - Temperature Stable

Operates effectively in a broad temperature range from -40°C to +80°C.

Products Customized

PP Honeycomb Panels can be tailored to meet the specific needs of different industries and applications. We offer customization in panel thickness, core cell size, surface material, and overall dimensions. Options include lamination with CFRT, fiberglass, aluminum sheets, or decorative films for enhanced functionality and appearance. Additional features such as PU foam layers, anti-slip coatings, or UV protection can also be integrated. From full-size panels to CNC-machined parts, we provide flexible solutions with reliable quality and rapid turnaround.

Lightweight. Unbreakable. Reliable.

In this real-world test, a full-grown adult steps directly onto our PP Honeycomb Panel—without any signs of bending, cracking, or damage. This visually compelling demonstration proves the panel’s exceptional strength-to-weight ratio, making it ideal for structural applications where both durability and lightness are essential.

Whether for truck flooring, RV interiors, or marine decks, our PP Honeycomb Panels deliver unmatched stability and resilience. Engineered for performance, trusted by industries worldwide.

Truck body

Lightweight yet durable panels that reduce vehicle weight while maintaining high structural integrity. Ideal for logistics vehicle walls, roofs, and floors.

RV

Provides a balance of strength and comfort, used in RV walls, ceilings, and furniture. Excellent thermal and acoustic insulation for long-distance travel.

Truck Parts

Perfect for truck floors, partitions, and side panels. Resistant to impact, moisture, and chemicals. Offers easy processing and installation.

Marine

Ideal for boat decks, cabin walls, and bulkheads. Corrosion-resistant, lightweight, and built to endure marine humidity and salt exposure.

WHY CHOOSE US

10+ Years of Expertise

With over a decade of focus on thermoplastic honeycomb and composite materials, we’ve developed deep technical expertise and a reputation for delivering high-performance, reliable solutions across global industries.

Trust

From Germany to the United States, from Brazil to Southeast Asia, our products are trusted by manufacturers in automotive, construction, marine, and logistics sectors. We’re proud to be a long-term partner for some of the world’s most demanding applications.

Quality

Every panel we produce undergoes strict quality control, from raw materials to final lamination. Our ISO-certified processes ensure that every delivery meets your technical and safety expectations.

Innovation

We invest in advanced equipment, including precision cutting, high-speed lamination, and automated assembly lines. Our R&D team continuously explores new materials and processes to meet evolving industry needs.

FAQ

Q1: What is a PP honeycomb panel?

A PP honeycomb panel is a composite panel made by bonding two rigid face sheets to a polypropylene honeycomb core. It combines lightweight properties with excellent mechanical strength, making it suitable for structural and decorative uses.

Q2: What are the typical applications?

They are widely used in automotive interiors, construction walls and partitions, transport containers, cleanrooms, and exhibition setups due to their strength, durability, and easy handling.

Q3: Can I choose custom surface materials and core specs?

Yes. We offer full customization of face skins (CFRT, fiberglass, aluminum, etc.), core thickness, cell size, and overall panel dimensions to meet your project needs.

Q4: Do you offer OEM/ODM services?

Absolutely. We support OEM, ODM, logo printing, pre-assembly, and more.